SÃĄp paraffin wax

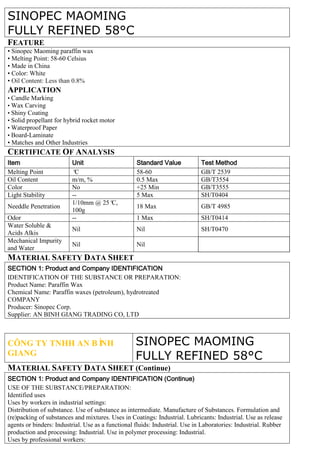

- 1. SINOPEC MAOMING FULLY REFINED 58°C FEATURE âĒ Sinopec Maoming paraffin wax âĒ Melting Point: 58-60 Celsius âĒ Made in China âĒ Color: White âĒ Oil Content: Less than 0.8% APPLICATION âĒ Candle Marking âĒ Wax Carving âĒ Shiny Coating âĒ Solid propellant for hybrid rocket motor âĒ Waterproof Paper âĒ Board-Laminate âĒ Matches and Other Industries CERTIFICATE OF ANALYSIS Item Unit Standard Value Test Method Melting Point °C 58-60 GB/T 2539 Oil Content m/m, % 0.5 Max GB/T3554 Color No +25 Min GB/T3555 Light Stability -- 5 Max SH/T0404 Needdle Penetration 1/10mm @ 25°C, 100g 18 Max GB/T 4985 Odor -- 1 Max SH/T0414 Water Soluble & Acids Alkis Nil Nil SH/T0470 Mechanical Impurity and Water Nil Nil MATERIAL SAFETY DATA SHEET SECTION 1: Product and Company IDENTIFICATION IDENTIFICATION OF THE SUBSTANCE OR PREPARATION: Product Name: Paraffin Wax Chemical Name: Paraffin waxes (petroleum), hydrotreated COMPANY Producer: Sinopec Corp. Supplier: AN BINH GIANG TRADING CO, LTD CÃNG TY TNHH AN BÃNH GIANG SINOPEC MAOMING FULLY REFINED 58°C MATERIAL SAFETY DATA SHEET (Continue) SECTION 1: Product and Company IDENTIFICATION (Continue) USE OF THE SUBSTANCE/PREPARATION: Identified uses Uses by workers in industrial settings: Distribution of substance. Use of substance as intermediate. Manufacture of Substances. Formulation and (re)packing of substances and mixtures. Uses in Coatings: Industrial. Lubricants: Industrial. Use as release agents or binders: Industrial. Use as a functional fluids: Industrial. Use in Laboratories: Industrial. Rubber production and processing: Industrial. Use in polymer processing: Industrial. Uses by professional workers:

- 2. Uses in Coatings: Professional. Lubricants: Professional (low release). Lubricants: Professional (high release). Use as release agents or binders: Professional. Use in agrochemicals: Professional. Use as a fuel: Professional. Use as a functional fluids: Professional. Use in road and construction applications: Professional. Use in Laboratories: Professional. Explosives manufacture & use: Professional. Use in polymer processing: Professional. Uses by consumers: Uses in Coatings: Consumer. Lubricants: Consumer (low release). Lubricants: Consumer (high release). Use in Agrochemicals: Consumer. Use as a fuel: Consumer. Use as a functional fluids: Consumer. Other Consumer Uses. Uses advised against: Not available. SECTION 2: HAZARDS IDENTIFICATION Classification: According to annex I of DIRECTIVE 67/548/EEC This substance is not classified in the Annex I of Directive 67/548/EEC. According to DIRECTIVE 67/548/EEC criteria Physical/Chemical Hazards: None. Health Hazards: None. Environmental Hazards: None According to EU CLP 2008 For physical-chemical properties: None. For health hazards: None. For environmental hazards: None. Labelling: Signal word: No signal word SECTION 4: FIRST AID MEASURES General advice: Remove contaminated clothing. Eye: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do so. Continue rinsing. If irritation, blurred vision or swelling occurs and persists, obtain medical advice from a specialist. If hot product is splashed into the eye, it should be cooled immediately to dissipate heat, under cold running water. Immediately obtain specialist medical assessment and treatment for the casualty. Skin: Remove contaminated clothing and footwear and dispose of safely, Wash affected area thoroughly with soap and water. Seek medical attention if skin irritation, swelling or redness develops and persists. For minor thermal burns. Cool the burn. Hold the burned area under cold running water for at least five minutes, or until the pain subsides. However, body hypothermia must be avoided. Do not put ice on the burn; Remove non-sticking garments carefully. DO NOT attempt to remove portions of clothing glued to burnt skin but cut round them. Seek medical attention in all cases of serious burns. CÃNG TY TNHH AN BÃNH GIANG SINOPEC MAOMING FULLY REFINED 58°C MATERIAL SAFETY DATA SHEET (Continue) SECTION 5: FIRE FIGHTING MEASURES Suitable Extinguishing Media Foam (Specifically trained personnel only), water fog (Specifically trained personnel only), dry chemical powder, carbon dioxide, sand or earth. Unsuitable Extinguishing Media: Do not use direct water jets on the burning product; they could cause splattering and spread the fire. Simultaneous use of foam and water on the same surface is to be avoided as water destroys the foam. Specific Hazard Avoid generating dust, particularly clouds of dust in a confined or unventilated space as dusts may form an explosive mixture with air, and any source of ignition, i.e. flame or spark, will cause fire or explosion.

- 3. Incomplete combustion is likely to give rise to a complex mixture of airborne solid and liquid particulates and gases, including carbon monoxide and unidentified organic and inorganic compounds. Special Protective Equipment for Fire-Fighters. In case of a large fire or in confined or poorly ventilated spaces wear full fire resistant protective clothing and self-contained breathing apparatus (SCBA) with a full face-piece operated in positive pressure mode. SECTION 6: ACCIDENTAL RELEASE MEASURES Personal Precautions and Emergency Procedures: Stop or contain leak at the source, if safe to do so. Avoid direct contact with released material. Keep non involved personnel away from the area of spillage. Alert emergency personnel. It is recommended to eliminate all ignition sources if safe to do so (e.g. electricity, sparks, fires, flares). If required, notify relevant authorities according to applicable regulations. Use personal protection recommended in Section 8. Environmental Precautions Do not flush into surface water or sanitary sewer system Methods and Material for Containment and Cleaning Up: Spillages onto land: Product in molten form: prevent product from entering sewers, rivers or other bodies of water. Note: solidified product may clog drains and sewers. If necessary dike the product with earth, sand or similar non-combustible materials. Let the material cool naturally. When inside buildings or confined spaces, ensure adequate ventilation. In case of solid product (e.g. flakes), avoid the generation and spreading of dust Collect solidified product with suitable mechanical means (e.g. shovels). Transfer collected product and other contaminated materials to suitable containers for recycle, recovery or safe disposal. Spillages on water or at sea: In case of spillages in the water, the product will cool down rapidly and become solid, floating on the surface. Contain product with floating barriers or other equipment. Collect by skimming or other suitable mechanical means. The use of dispersants should be advised by an expert, and, if required, approved by local authorities. Collect recovered product and other materials in suitable containers for recycle, recovery or safe disposal. CÃNG TY TNHH AN BÃNH GIANG SINOPEC MAOMING FULLY REFINED 58°C MATERIAL SAFETY DATA SHEET (Continue) SECTION 7: HANDLING AND STORAGE Handling: Avoid splash filling of bulk volumes when handling hot liquid product. Precautions should be taken to avoid skin burns when handling hot product. Avoid breathing dust/fume/vapours. Prevent the risk of slipping. Use personal protective equipment as required. For more information regarding protective equipment see section "Exposure controls/personal protection" Storage: Storage area layout, tank design, equipment and operating procedures must comply with the relevant European, national or local legislation. Protect drains from spills and prevent entry of molten material, since this may result in blockage on cooling. Cleaning, inspection and maintenance of internal structure of storage tanks must be done only by properly equipped and qualified personnel as defined by national, local or company regulations. Store separately from oxidizing agents. Recommended materials: Liquid product: for containers, or container linings use mild steel, stainless steel. Solid product: pressboard boxes. Unsuitable materials: Some synthetic materials may be unsuitable for containers or container linings depending on the material specification and intended use. Compatibility should be checked with the manufacturer.

- 4. SECTION 8: EXPOSURE CONTROLS 1 PERSONAL PROTECTION (Continue) Personal protective equipment Eye/face protection Wear appropriate protective eyeglasses or chemical safety goggles as described by OSHA's eye and face protection regulations in 29 CFR 1910.133 or European Standard ENI 66. Hand protection Wear appropriate protective gloves to prevent skin exposure. Skin protection Wear appropriate protective clothing to prevent skin exposure. Respiratory protection A respiratory protection program that meets OSHAs 29 CFR 1910.134 and ANSI Z88.2 requirements or European Standard EN 149 must be followed whenever workplace conditions warrant respirator use. General hygiene considerations No smoking, No eating or drinking in workplace. Wear goggle while working with. Wash skin before eating or drinking. Environmental exposure controls Local exhaust ventilation usually required. As much as possible, keep from being washed into surface waters.