Utilizing Online TOC Monitoring to Control Industrial Water Quality

- 1. UTILIZING ONLINE TOC MONITORING TO CONTROL INDUSTRIAL WATER QUALITY

- 2. IMPORTANCE OF MONITORING INDUSTRIAL WATER QUALITY Industrial Water Types include: • Processing • Cooling • Heating • Cleaning • Condensate • Surface/Storm • Grey water • Wastewater • Water for recycling Online Total Organic Carbon (TOC) monitoring can play a part in managing all types… 2

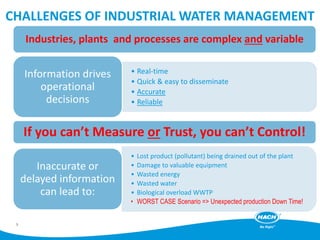

- 3. CHALLENGES OF INDUSTRIAL WATER MANAGEMENT Industries, plants and processes are complex and variable • Real-time • Quick & easy to disseminate • Accurate • Reliable Information drives operational decisions If you can’t Measure or Trust, you can’t Control! • Lost product (pollutant) being drained out of the plant • Damage to valuable equipment • Wasted energy • Wasted water • Biological overload WWTP • WORST CASE Scenario => Unexpected production Down Time! Inaccurate or delayed information can lead to: 3

- 4. ABILITY TO MEASURE >>> CHANGES BEHAVIOR Speed Camera Driver behavior changes almost instantly.

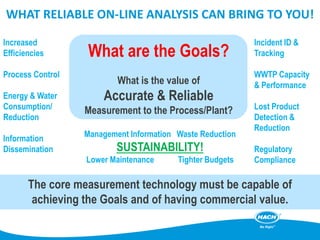

- 5. What are the Goals? What is the value of Accurate & Reliable Measurement to the Process/Plant? The core measurement technology must be capable of achieving the Goals and of having commercial value. Increased Efficiencies Process Control Energy & Water Consumption/ Reduction Information Dissemination Incident ID & Tracking WWTP Capacity & Performance Lost Product Detection & Reduction Regulatory Compliance Management Information Waste Reduction SUSTAINABILITY! Lower Maintenance Tighter Budgets WHAT RELIABLE ON-LINE ANALYSIS CAN BRING TO YOU!

- 6. 6 SOLUTION TO INDUSTRIAL CUSTOMERS

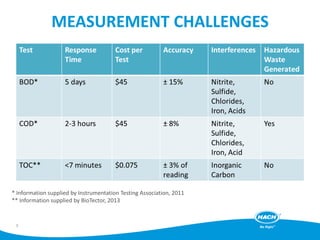

- 7. MEASUREMENT CHALLENGES 7 * Information supplied by Instrumentation Testing Association, 2011 ** Information supplied by BioTector, 2013

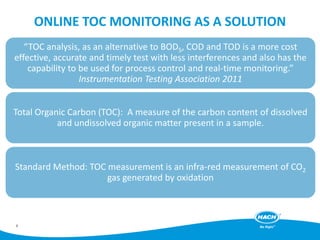

- 8. ONLINE TOC MONITORING AS A SOLUTION “TOC analysis, as an alternative to BOD5, COD and TOD is a more cost effective, accurate and timely test with less interferences and also has the capability to be used for process control and real-time monitoring.” Instrumentation Testing Association 2011 Total Organic Carbon (TOC): A measure of the carbon content of dissolved and undissolved organic matter present in a sample. Standard Method: TOC measurement is an infra-red measurement of CO2 gas generated by oxidation 8

- 9. WHY IS TOC MONITORING NOT USED MORE WIDELY?

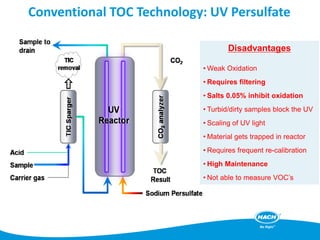

- 10. Conventional TOC Technology: UV Persulfate Disadvantages • Weak Oxidation • Requires filtering • Salts 0.05% inhibit oxidation • Turbid/dirty samples block the UV • Scaling of UV light • Material gets trapped in reactor • Requires frequent re-calibration • High Maintenance • Not able to measure VOC’s

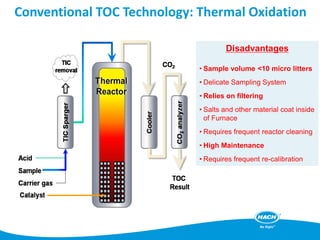

- 11. Conventional TOC Technology: Thermal Oxidation Disadvantages • Sample volume <10 micro litters • Delicate Sampling System • Relies on filtering • Salts and other material coat inside of Furnace • Requires frequent reactor cleaning • High Maintenance • Requires frequent re-calibration

- 12. TYPICAL ONLINE TOC ISSUES Frequent Maintenance & Service – High cost of ownership Low Reliability – Lack of trust analyzer will be running when an incident occurs Signal Drift – Lack of confidence in the results provided Filtering – Removes what should be measured

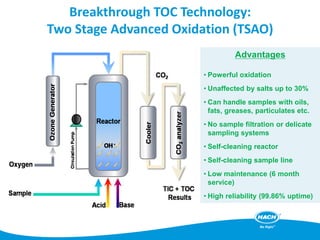

- 13. Breakthrough TOC Technology: Two Stage Advanced Oxidation (TSAO) Advantages • Powerful oxidation • Unaffected by salts up to 30% • Can handle samples with oils, fats, greases, particulates etc. • No sample filtration or delicate sampling systems • Self-cleaning reactor • Self-cleaning sample line • Low maintenance (6 month service) • High reliability (99.86% uptime)

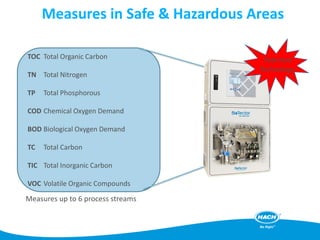

- 14. Measures in Safe & Hazardous Areas Measures up to 6 process streams TOC Total Organic Carbon TN Total Nitrogen TP Total Phosphorous COD Chemical Oxygen Demand BOD Biological Oxygen Demand TC Total Carbon TIC Total Inorganic Carbon VOC Volatile Organic Compounds Patented Technology

- 15. NOT JUST FOR ENVIRONMENTAL COMPLIANCE…

- 16. HOW DO CLIENTS GET THESE RESULTS FROM ONLINE TOC MONITORING?

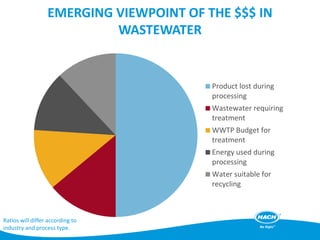

- 17. EMERGING VIEWPOINT OF THE $$$ IN WASTEWATER Product lost during processing Wastewater requiring treatment WWTP Budget for treatment Energy used during processing Water suitable for recycling Ratios will differ according to industry and process type.

- 18. Production & WWTP functions need to work together to optimise overall plant operations Online TOC monitoring enables shared process insights, accountability and increased efficiencies

- 19. RELIABLE PERFORMANCE IN DIFFICULT APPLICATIONS

- 20. SOME WATER QUALITY APPLICATIONS • Condensate Return Water • Cooling Water • Boiler Condensate

- 21. CONDENSATE RETURN WATER Why measure it? • Boiler protection • Water reuse optimisation • Energy optimisation • Chemical/additive cost reduction • Make-up water cost reduction • WWTP treatment cost reduction

- 22. Process breakthrough in a heat exchanger will contaminate condensate return water and will damage the boiler Steam Boiler Feed & Anti-Corrosion Additives To drain diversion @ >5ppm approx Condensate return water is valuable because of the cost of treatment Condensate Return Process In Process OutProcess Out Process InProcess In Process OutTOC Condensate Return Application

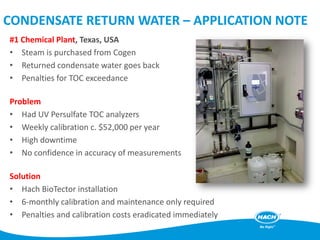

- 23. CONDENSATE RETURN WATER – APPLICATION NOTE #1 Chemical Plant, Texas, USA • Steam is purchased from Cogen • Returned condensate water goes back • Penalties for TOC exceedance Problem • Had UV Persulfate TOC analyzers • Weekly calibration c. $52,000 per year • High downtime • No confidence in accuracy of measurements Solution • Hach BioTector installation • 6-monthly calibration and maintenance only required • Penalties and calibration costs eradicated immediately

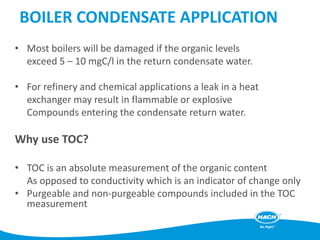

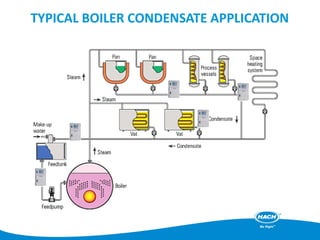

- 24. BOILER CONDENSATE APPLICATION • Most boilers will be damaged if the organic levels exceed 5 – 10 mgC/l in the return condensate water. • For refinery and chemical applications a leak in a heat exchanger may result in flammable or explosive Compounds entering the condensate return water. Why use TOC? • TOC is an absolute measurement of the organic content As opposed to conductivity which is an indicator of change only • Purgeable and non-purgeable compounds included in the TOC measurement

- 25. TYPICAL BOILER CONDENSATE APPLICATION

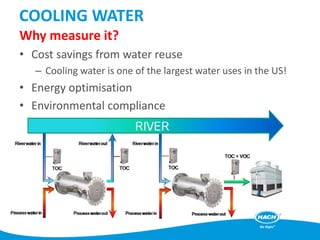

- 26. Why measure it? • Cost savings from water reuse – Cooling water is one of the largest water uses in the US! • Energy optimisation • Environmental compliance COOLING WATER

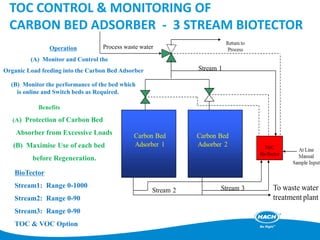

- 27. TOC CONTROL & MONITORING OF CARBON BED ADSORBER - 3 STREAM BIOTECTOR Process waste waterOperation (A) Monitor and Control the Organic Load feeding into the Carbon Bed Adsorber (B) Monitor the performance of the bed which is online and Switch beds as Required. Benefits (A) Protection of Carbon Bed Absorber from Excessive Loads (B) Maximise Use of each bed before Regeneration. BioTector Stream1: Range 0-1000 Stream2: Range 0-90 Stream3: Range 0-90 TOC & VOC Option

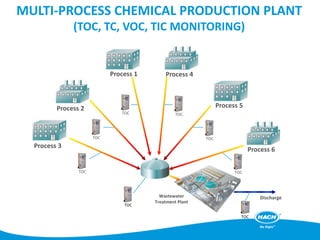

- 28. MULTI-PROCESS CHEMICAL PRODUCTION PLANT (TOC, TC, VOC, TIC MONITORING) Process 1 Process 2 Process 3 Process 4 Process 5 Process 6 DischargeWastewater Treatment Plant TOC TOC TOC TOC TOC TOC TOC TOC

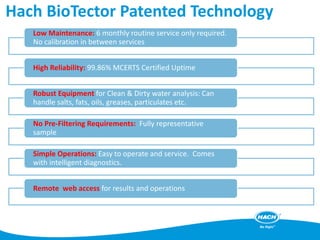

- 29. Low Maintenance: 6 monthly routine service only required. No calibration in between services High Reliability: 99.86% MCERTS Certified Uptime Robust Equipment for Clean & Dirty water analysis: Can handle salts, fats, oils, greases, particulates etc. No Pre-Filtering Requirements: Fully representative sample Simple Operations: Easy to operate and service. Comes with intelligent diagnostics. Remote web access for results and operations Hach BioTector Patented Technology

- 30. THE RACE TO SAVE THE ENVIRONMENT STARTS WITH YOUR 1ST STEP… ARE WE READY! The world’s water, energy and food systems are tightly linked. Water is needed to extract energy and generate power, Energy is needed to treat and transport water; and both water and energy are needed to grow Food. In the coming decades these vital resources will come under greater pressure. Working across industries and sectors will help address their complex relationship, known as the energy-water-food nexus.

- 31. THANK YOU