cv 2016 dec

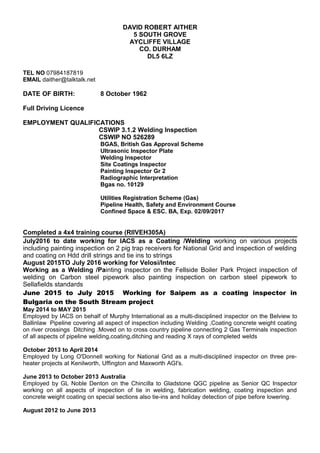

- 1. DAVID ROBERT AITHER 5 SOUTH GROVE AYCLIFFE VILLAGE CO. DURHAM DL5 6LZ TEL NO 07984187819 EMAIL daither@talktalk.net DATE OF BIRTH: 8 October 1962 Full Driving Licence EMPLOYMENT QUALIFICATIONS CSWIP 3.1.2 Welding Inspection CSWIP NO 526289 BGAS, British Gas Approval Scheme Ultrasonic Inspector Plate Welding Inspector Site Coatings Inspector Painting Inspector Gr 2 Radiographic Interpretation Bgas no. 10129 Utilities Registration Scheme (Gas) Pipeline Health, Safety and Environment Course Confined Space & ESC. BA, Exp. 02/09/2017 Completed a 4x4 training course (RIIVEH305A) July2016 to date working for IACS as a Coating /Welding working on various projects including painting inspection on 2 pig trap receivers for National Grid and inspection of welding and coating on Hdd drill strings and tie ins to strings August 2015TO July 2016 working for Velosi/Intec Working as a Welding /Painting inspector on the Fellside Boiler Park Project inspection of welding on Carbon steel pipework also painting inspection on carbon steel pipework to Sellafields standards June 2015 to July 2015 Working for Saipem as a coating inspector in Bulgaria on the South Stream project May 2014 to MAY 2015 Employed by IACS on behalf of Murphy International as a multi-disciplined inspector on the Belview to Ballinlaw Pipeline covering all aspect of inspection including Welding ,Coating concrete weight coating on river crossings Ditching .Moved on to cross country pipeline connecting 2 Gas Terminals inspection of all aspects of pipeline welding,coating,ditching and reading X rays of completed welds October 2013 to April 2014 Employed by Long O'Donnell working for National Grid as a multi-disciplined inspector on three pre- heater projects at Kenilworth, Uffington and Maxworth AGI's. June 2013 to October 2013 Australia Employed by GL Noble Denton on the Chincilla to Gladstone QGC pipeline as Senior QC Inspector working on all aspects of inspection of tie in welding, fabrication welding, coating inspection and concrete weight coating on special sections also tie-ins and holiday detection of pipe before lowering. August 2012 to June 2013

- 2. Employed by John Hewitt, IACS for Murphy International as a multi-disciplined Inspector on the East Wall to Santry pipeline covering all aspects of pipeline welding, coating also concrete weight coating on special section and ultrasonics as well as the interpretation of X-ray radiographs. September 2007 to August 2012ŌĆō Employed by OŌĆÖNeill Inspection & Testing Ltd for Northern Gas Networks as a Senior Site inspector covering all welding Carbon Steel and coating including concrete weight coating on river sections on United Utilities and Northern gas Network assignments. April 2007 to August 2007 ŌĆō Employed by IACS as a Multi-disciplined Inspector on the National Grid Nether Kellet-Pannal Pipeline covering special sections tie ins and concrete weight coating on marsh sections February 2007 to March 2007 ŌĆō Employed as a Coating Inspector by Oceaneering on oil pipeline, location ŌĆō Yemen. Inspection of MCL coating onto girth welds. Duties included ŌĆō monitoring and evaluating atmospheric conditions applicable to application of coatings. Checking blast standards, salt testing, DFTŌĆÖs and holiday detection of finished coating, as per project specification. February 2006 to December 2006 - Employed by IACS as a Multi-disciplined Inspector on the National Grid Nether Kellet-Pannal Pipeline covering special sections and tie-ins including concrete weight coating in special sections August 2005 to January 2006 Employed by Hereema Hartlepool Ltd at first as a painting/coating inspector then promoted to painting coordinator whose duties included stock control, ensuring projects were completed to schedule and managing the most efficient use of the workforce. Liaising with fireproofing, welding and logistics departments to ensure safe working conditions and completion times. March 2005 to July 2005 Employed by OŌĆÖNeill Inspection & Testing Ltd on the Churchover to Newbold Pacey pipeline as a multi-disciplined inspector carrying out welding, coating, backfill and ditching concrete weight coating inspection. October 2004 to December 2004 - Employed by Hereema Hartlepool Ltd carrying out coating and painting inspection at four offsite facilities including the inspection of Fusion Bonded Epoxy coatings on pipework at Barrier Coating Wallsend. September 2004 ŌĆō Employed by IACS carrying out various inspection duties, including painting of two AGIŌĆÖs in the Southampton area and witnessing welding tests on Carbon Steel procedures on behalf of Skanska for the Isle of Grain LNG plant project. April 2004 to September 2004 - Employed by IACS working on behalf of Murphy Pipelines as a welding/coating,also carried out inspection of concrete weight coating for lake crossings inspector on the Carrickfergus to Londonderry BDE Northwest Pipeline. April 2003 to March 2004 ŌĆō Employed by NRL on the TRANSCO Kings Lynn to Bacton 48ŌĆØ pipeline as a multi-disciplined inspector.Duties included inspection of concrete weight coating on tidal land Then moved on to the A77 pipeline diversions inspection of welding and coating including assisting SPI with HOT TAP welding operations. February to April 2003 ŌĆō Employed by OŌĆÖNeill Project Services as a multi-disciplined inspector carrying out welding and coating inspection for UMAX Pipelines at their spool base in Mobile, Alabama, USA. July to September 2002 ŌĆō Employed by NRL as a multi disciplined inspector on behalf of Rugby Cement. June 2002 to July 2002 ŌĆō Employed by NRL on the Cambridge to Matching Green 48ŌĆØ pipeline as a multi-disciplined inspector, duties including inspection of welding and coating both mainline and concrete coated areas October 2001 to May 2002 ŌĆō Employed by AICS on two projects. First project, carrying out welding and coating inspection for the Channel Tunnel rail link on behalf of Murphy Pipelines inspection of concrete coated pipes on river crossings. Second project, carrying out load in inspection of pipes and

- 3. fittings, also mainline and fabrication welding on behalf of TRANSCO on the 36ŌĆØ Willington to Steppingley cross country pipeline. March 2001 to September 2001 ŌĆō Employed by NRL. First Project ŌĆō Huntingdon to Willington 36ŌĆØ TRANSCO pipeline. Duties included inspection of the pipe, entering pipe dump for coating and mechanical damage, cross checking pipe and cast numbers against pipe delivery lists as well as inspection of pipe stringing and mainline and tie-in welding. Second Project ŌĆō Nailsea to St. George 48ŌĆØ TRANSCO pipeline. Duties include inspection of fabrication and tie-in welding, coating inspection before ditching and tie-in coating. November 2000 to March 2001 ŌĆō Employed by AICS for Murphy Pipelines carrying out inspection of welding , including concrete weight coating coating on various diameter gas and water pipes for the Channel Tunnel rail link. September to November 2000 ŌĆō Employed by OŌĆÖNeill Ltd. as a multi disciplined inspector on the Ponteland to Dinnington 36ŌĆØ TRANSCO pipeline. Inspection of the welding , coating,ultrasonic testing of cut put ends for laminations and concrete weight coating for marsh land June to September 2000 ŌĆō Employed by NRL on the Sutton-on-the-Hill to Drointon 48ŌĆØ TRANSCO gas pipeline inspecting the welds of fabrications and tie-ins. April 2000 to June 2000 ŌĆō Employed by Murphy Pipelines as a coating inspector and concrete weight coating on pipes on the BP Chemicals Teeside ŌĆō Saltend pipeline. August 1999 to September 1999 ŌĆō Employed by Kvaerner Process on the Dunstable to Northampton, Rugby Cement pipeline carrying out inspection of pipe fabrication, pipe coating and pipe ditching. April 1999 to July 1999 - Employed by NRL on the Churchover to Newbold Pacey gas pipeline carrying out inspection of mainline welding and fabrications. October 1998 to March 1999 ŌĆō Employed by Powerjet Ltd. (previously Highlander Ltd.) applying various coating and lining systems as previous. June 1998 - September 1998 ŌĆō Employed by Roxby Engineering International to work with Glendee Engineering on the Transco Duffryn to Pentrebain cross-country gas pipeline. The project involved inspection of welding , coating concrete weight coating on special sections on the pipeline ensuring the relevant procedures and method statements were complied with. January 1998 - June 1998 - Employed by Highlander Ltd. applying various coating and lining systems to tanks and vessels. This included stainless steel plate lining of coal hoppers, tiling of chute sections and coating of tanks with glass-flake systems. Also carrying out the quality control inspection on most contracts. August 1997 - December 1997 - Employed by Solus testing on Middleham Bridge Strengthening Project. Inspection of welding and painting involved in bridge strengthening, including inspection in- house of fabrications and coating applications. Supervising all aspects of non-destructive testing. August 1996 - August 1997 - Employed by Highlander Ltd., applying various coating and lining systems to tank vessels and bunkers. Included the application of glass flake systems and solvent free paint systems, lining bunkers with anti-friction tiles and UHWPE plastic. October 1995 - July 1996 - Employed by A-Tech Fabrications, shot blasting and applying surface coatings to various steel fabrications. May 1995 - September 1995 - Employed by OIS Ltd. as a painting inspector on site in the East Midlands area for British Gas Transco. November 1994 - April 1995 - Employed by Loritech Ltd applying various surface coatings to the interior of storage tanks.

- 4. August 1994 - October 1994 - Employed by OIS Ltd as a painting inspector on various contracts for Eastern Gas and East Midlands Gas. December 1993 - August 1994 - Working for Loritech Ltd. on various tank-lining contracts carrying out surface preparation and application of relevant coatings including solvent free urethane and glass flake. March 1993 - November 1993 - Employed by Solus Schall on the BGC Skitter to Hatton and Silk Willoughby to Peterborough pipelines as a coating inspector responsible for the bending inspection of pipes and painting inspection of above ground installation. December 1991 - November 1992 - Contracted by R D Recruitment to SLP Engineering Ltd. on the Amerada Hess Scott Field as a painting inspector responsible for the painting and fire-proofing of two drilling modules including the metal spraying of the flare boom. October - December 1991 - Worked for Solus Schall on the EMGAS Immingham - Tioxide pipeline as a coating/welding inspector. May - September 1991 - Employed by Roxby Engineering Ltd. on the Castle Douglas - Newton Stuart pipeline as a mainline coating inspector on behalf of Scottish Gas and the Shell NWEP from Grange Town to Moffat as a front-end welding inspector. January - April 1991 - Contracted by Solus Schall working on the Maelor to Bridge Road pipeline as a coating/welding inspector on behalf of Wales Gas and on BPA Tring Diversion as a coating/welding inspector. April - December 1990 - Employed by Roxby Engineering International Ltd., Sidcup, Kent. From July to December worked on the Easington - North Ravenspur project on behalf of the Norwest Holst Quality Assurance Department inspecting painting, welding and fireproofing. From April to July employed by Mapel as a welding/coating/painting inspector during construction of the Humberside - Lincoln cross- country pipeline project for Petrofina. 1989 - 1990 - Worked for Solus Oceaneering as a welding/coating inspector on various projects including inspection of fusion bonded epoxy coating for British Hydrocarbons. Also welding inspection on the Overton - Owestry pipeline and painting inspection for Wales Gas on various gasholders throughout South Wales. 1987 - February 1988 - Worked as a coating/painting inspector for Atkins Inspection Services Ltd. and on the application of epoxy coating , on the Audley Milwich pipeline. This was followed by inspection of the coating of AGI. Following this project, worked on the Theddle Thorpe/Hatton pipe storage depot inspecting pipes entering the depot for coating and bevel damage, making sure pipes were unloaded and stacked in accordance with specification. 1981 - 1986 - Employed by Britblast Ltd. and ARV Blasting of Newton Aycliffe Industrial Estate, Co. Durham. Blast-cleaning surface coated steel to appropriate British and Swedish Standards.