Ptsc profile 2016

- 1. Cutting tool ®C Metrology ®C Maintenance Tool CO.,LTD. ptsc.cuttingtools www.ptsc.co.th sales@ptsc.co.th 20th Anniversary

- 2. GOdrill? ®§°ß?????°§??????? Dia. 1.0®C12.7 mm. Flat Bottom Drill ®§°ß?????°§??????? Dia. 3.0®C21.0 mm. Drill Fix DFT Dia. 24-80 mm. KENTIP Dia. 7.94-27.99 mm. KSEM Dia. 12.5 ®C 40.0 mm. ????????®¢??®§??????®§?????? ???????????????????? ????????°Ë?????????°Ï Kennametal ???????? ???? 20 ?? ?????????°Ë?? ???????? 100 ?????°§ ®§?? ??°Ë????????°ß°§??°ß????®§??? ????????°§???????????? °§????????°§???????????? ?????????°Ï®§??? ®§???°Ï®¢°Ë? °§???°Ï???°Ë?????®§??°§???°ß? ???°§???°ß??????°¡? ????????®¢??®§??????®§??????®§????°§ °ß?? Kennametal °ß?°§?????°§????????°ß®§?°¡??°Ï ??????????°Ï??°§??????????????°Ï®§??? ?????°ß???????????????°ß?????°Ë??°ß?? ??°Ï°Ï???????????®§?°¡?°Ï?°§??????? Tool life ®§??????????????°Ï®§??? ???°ß???????°Ï ????°§????????°§?? ®¢?? cycle time ?????????? KSEM PLUS Dia. 28.0 ®C 70.0 mm. °Ï??®§°ß?? Holemaking ??????°Ë???? ModBORE? Fine Boring Dia. 23.9-105.1 mm. °Ï?????°Ï Turning ®§??????®§????°§ PCBN ??????? ®§?????????°Ï ??????°Ï°Ï?????? A4 ®§??????®§????°§°§?????°Ï Threading, Grooving, and Cut-Off ®§?????????°Ï®§?????°Ë ®§?????????°Ï Stellram ????????°§??°Ï®¢°§?°Ï ®§?????????°Ï®§????? Stellram ®§?????????°Ï CBN ®§?????????°Ï ®§°Ë???®§??°§°§?? ®§????®§?????????°§?°Ï®¢????????®§???????? ?????????°§???®§?°¡??®§???®§?°¡????????°Ï??°§??????????????????°Ï®§??? STELLRAM ®§????????????????°Ï°Ï??®¢???®§?????? ®¢??????? Inconel ??°¡? Titanium Top Notch ???°Ï??????? www.ptsc.co.th

- 3. KenFeed DodekaTM Face Mills KSSM8+? Harvi II? ???????®§??? ?????®§???? Harvi I ? Harvi II? Mill 4-15 KenFeed Mini GoldRodekaTM Face Mills °ß??????????®§??????°§?????®§?°§ °§??°Ï°Ë??????? ®¢?? HSS ?????®§?°¡?? 2-6 ??? ???????????? ??? ????®¢??????°Ï®§???°§????? ?????®§????®§????®§??????????????? ???®§?????®§??°Ë??? KenFeed GOmill? ???®§?????? Endmill °Ï????? Milling °Ï????? Milling ®¢??®§??????®§??????®§????°§ www.ptsc.co.th

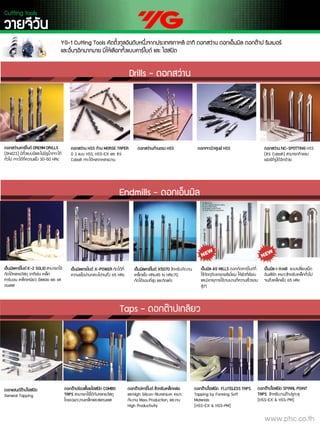

- 4. ®§??????°Ë??????? X5070 ??????????°Ï?? ®§????®¢??°Ï HRc45 to HRc70, ?????????°§????°Ï ®¢?????®¢??°Ï ®§??????°Ë?????? X-POWER ??????°§?? °Ë???®¢??°Ï??????°Ï??°ß???°Ï 65 HRc ???®¢?????????????? General Tapping ??????????°Ï®§?°¡????????? COMBO TAPS ???????????????????????? ???®§????°Ï??®§????®¢???®¢??®§?? ???????°Ë??????? ???????®§???????? ®¢??High Silicon Aluminium ®§???? ???°Ï?? Mass Production, ®¢??°Ï?? High Productivity ????????????? FLUTELESS TAPS Tapping by Forming Soft Materials (HSS-EX & HSS-PM) ???????? HSS ???? MORSE TAPER ?? 3 ®¢?? HSS, HSS-EX ®¢?? 8% Cobalt ®§°ß?????????????°Ï?? ??????????????°Ï HSS ???®§°ß?????????? HSS ???????? NC-SPOTTING HSS (8% Cobalt) ??????°§??®¢?? ®§????°§?????????????? YG-1 Cutting Tools °Ë?????°Ï°§????????????°Ï°ß?????®§°§?®§????? ??°§? ???????? ???®§?????? ??????? ???®§???? ®¢???°¡???????????? ?????®§?°¡??°§??°Ï®¢??°Ë??????? ®¢?? ?????? ????????????? SPIRAL POINT TAPS ???????°Ï????????°§??? (HSS-EX & HSS-PM) ®§??????°Ë??????? K-2 SOLID ????????? ??????????????? ??°§?®§??? ®§???? °Ë?????? ®§????®§????? ?????? ®¢?? ®¢? ??®§?? ®§?????? 4G MILLS ??????°Ë???????°§?? ???????????®§??????®§????? ??????°§??®§???? ®¢??????????????°Ï?????°§??°Ë???®§?????? ??°Ï? ????????°Ë??????? DREAM DRILLS (DH423) ??°§??°Ï®¢????®¢?????????????®§°ß????? °§????? ®§°ß?????°§??°Ë???®¢??°Ï 30-50 HRc ®§?????? i-Xmill ®¢??®§??????®§??? ???®§????°§ ®§???????????®§????°§????? °ß???°Ï®§????®¢??°Ï 65 HRc Drills - ???????? Endmills - ???®§?????? Taps - ???????®§????? ???°ß???? Cutting tools www.ptsc.co.th

- 5. ®§??????? VRX ???????°Ï?????°Ï®§??????®§?? ????°Ï°Ë? ???°Ï???????????????? ®§?????????°Ï®§?????°Ï??°§????? ®§??? VKX ®§??? VTX ®§??? VCB ®§???? Stainless ????????????®§????, ®§???????? ®§????°§?°Ë??????? ®¢?? ?°§°§?®§???? ®§??? VM7 ®§??? VK2 ®§??? VK2P ®§?????????? Gen ???®¢??? CNC ???????°Ï?? ??? ®¢?????°Ï®§????????°§?????????®§???°Ë?????°ß??? THREADING TOOLS MiniPro ???°Ï®§??????? ??®§??? Helical From M3x0.5 MilliPro From M1.6x0.35 MilliPro HD From M2.0x0.40 Straight From M3x0.5 Deep Thread From M6x1.0 Full MilliPro Dental From M1.0x0.25 °Ï??®§????? Heicool From M3x0.5Helicool_R From M6x1.0 Helicool_C From M6x1.0 HTC : 3 in 1 Gear : machining both straight and helical teeth °Ë???°Ë???????????? ???°Ï®¢?? 0.2-6.0mm or DP 128.0-4.0. Spline : machining both involute or straight- sided profiles °Ë???°Ë???????????? ???°Ï®¢?? 0.5-6.0mm or DP 48/96 - 4/8. Rack milling tools °Ë???°Ë???????????? ???°Ï®¢?? 0.2-6.0mm or DP 128.0- 4.0. Thread Milling Tools ??????®§????? ??????°Ï???®§???°Ï ®§°ß?? + °§??®§????? + ®¢??®§???? From M6x1.0 ®§?????????°Ï®§????? 6 ??? ARBORS ???°ß?? Birla Precision ???????°Ï? ???????®¢???????°Ï???????°§?????? ???°ß??°§?????????°Ï? www.ptsc.co.th

- 6. ®§?°¡??°Ë?????°Ï???°Ë??°Ë??°Ë????? ???°ß??? ??°¡?????°Ï®¢??°ß????°Ï ??????? °Ë??°ß??????®§°Ë?°¡??°Ï?°¡?????°Ï Master3DGage (Powered by Verisurf°Øs industry-leading inspection software). ®§??? ???????®§°Ë?°¡??°Ï?°¡???????????®¢?????? ??°Ë?????????????????? ®¢??°Ë??°Ë??????????°Ï®§°Ë?°¡??°Ï?°¡??????????? ®§°Ë?°¡??°Ï CMM ®¢?????? Portable CMM THREADING TOOLS ®§°Ë?°¡??°Ï???°ß???°§????? ????????°Ï??????°ß?????????°Ï°§??®¢????®§°Ë????????°§??°Ï????°Ï®§°Ë?°¡??°Ï°ß??? ®¢?? ????°§????? °Ë?????°Ï??????°Ï°§??°ß?®§???????®¢?????°Ë??°Ë?? ???®§°Ë?°¡??°Ï°ß???®¢??®§°Ë?°¡??°Ï?°¡???°Ï°§?????? ????????°§??°ß??????? : ? ®§??????????????°Ï????°Ï°Ë?????°Ï°§?? ? ?????®§?????????? ? ?°¡?????®§°Ë?°¡??°Ï°ß??? CNC ? ????????®§?????°ß????? Machine ? ?????°Ï®§°Ë?°¡??°Ï°ß??? ? ?????°Ï????°Ï??°ß?????®§????????°Ï°§?? ? ?????°Ï°§??®§????????????°Ï??? machine

- 7. OMV SoftwareTool Setting on CNC TRS2 - Tool Break Sensor ??????????????°Ï????®§°Ë?°¡??°Ï??? ????°Ï®¢?????? ?????°Ï??????®¢?? ?????®§?? ???®¢?????????°ß?????????°Ï????°Ï?? ??®§°Ë?°¡??°Ï°ß??? CNC ®§???????????°Ï?? ®¢??????? ??°¡?????????°§????°Ë?????®§??????°Ï ®§??°Ë°Ë?????? ®¢?? diameter ??°Ï°§?? ?????®¢°ß?°Ï®§?°¡??°§???????? ??? ????????? ®§??°Ë°§?????????? 1 ????°§? ®§??°Ë°§?????®§?????? °§?? Dia 0.2 mm. ®§°Ë?°¡??°Ï?°¡????????°Ï??®¢?????°§?????????®§°Ë?°¡??°Ï CNC Machine Probing on CNC ???????°§?????????! ??°Ë?? ????°§??°Ï ?????????°Ï°Ë???????????????°¡????? ???°Ë????????°Ï?????®§??? ®§???°Ï??????????®§?????°Ï°Ë???????®§?? ???®¢??? Repair By Exchange (RBE) ??°Ï®§??°ß?°ß?????®§????????????????????? 1-2 ???**?????????????????????? PTSC ®§?????????®§??? ®¢??°ß??????? ??????? ®¢??®§°Ë?°¡??°Ï?°¡??????°Ï Renishaw ????????? 15?? ??????®§???????? ®§???????®§????????°Ë??????????? ???! CMM Styli for Probe HeadProbe body and ModuleProbe heads Clamping Kit Renishaw Equator ®§°Ë?°¡??°Ï?°¡?????®§??????°Ï°Ë? ???????? SP25 ????????®¢??????°Ï?? ? ???®§?????®§°§????????????????????????????????????°Ï??°Ï??°Ï ? ®¢??°Ï®¢???°Ï ®C ????°ß??®¢???°ß???°¡??°§??????®¢?? '??????????°Æ ??????????? ???°Ï°Ë????????®§???????????????????????????°Ï???°§?????®§???? ? ????????????????????°Ï???????????? ®¢????????®§???????®¢??????? ???????°Ï???®§?????????®§??????®¢??°Ï??°Ï??????®¢?? ? °Ë???????????????°§?°Ï????????????®§°Ë?????°Ë????????????°Ï®§??????®¢?? ???????????? SP25 ???°Ï??????®¢??????°§?????®§??? ? ®§?????????®¢??????°Ï?????°§??°§? ???°Ï°Ë?????????°Ï???®§??? ???????????®§??®§????®§°§?????? ®¢????????°Ï?????°ß????? ?????????????®§????®§?????????????? ??????? Renishaw 02-3704900 (auto 10 lines) Probe head , Module ®¢?? Stylus ??????? CMM ??????? ®§°Ë?°¡??°Ï?°¡???? Machine Tools Probing System www.ptsc.co.th

- 8. ????°Ï???°Ë???°Ë? Ergonomic Stereo microscopes Superior imaging for a wide range of inspection & rework tasks Mantis Compact ®¢?? Mantis Elite ®§??????°Ë???°Ë?°§?????®¢?????°Ï??°Ï???®¢????®§?? ?????°§???®§??????°Ï°§?°Ï Vision engineering ???®¢??®§?°¡?? ????????????????????°Ï???????®¢???°Ï??? ?????????°§??®§??????®¢????????????????°ß????????°Ï??°§??????°¡?????°Ï????????????®§???°§?????°ß???????°Ï?? ???????°Ï ®§?°¡???????°§????°§??®§???????? ?????????????°§?? 2X-20X ?????°§??°Ï???????????? Digital camera ???°§?°Ï Monitor ?????????? Kestrel Elite ®¢?? Swift °Ë°¡? ???°Ë???°Ë???????????? °§?????°Ï??°§???? °Ë????????????????? ®¢??°Ë??? ®¢?????? °Ë???°§?°§????°Ï ??????? ???®¢???????????°§?????°Ï??°Ï??? ®¢???? ??°Ï?????????°§??°Ï??°§??°Ë??°Ë?? Hawk °Ë°¡????°Ë???°Ë? High precision measurement °§?????°Ï?? ???°§??°Ï®¢?? 2 ®¢?? ®¢?? 3 ®¢?? ?????°§??°Ï????????°Ï??°§????????? 400 x300 mm. ®¢???????? Hawk CNC ??????®§???????®¢???®§?°¡?? ??????????°Ï??®¢??????????? Non-Contact Measuring Microscope For precision measurement and inspection Non-Contact Measuring Microscopes For precision measurement and inspection of 3-dimensional parts Microscope Precision Tooling Services Co., Ltd. 88 Nimitkul Tower, 3rd Floor, Rama9 Soi 57/1 (Visetsuk2), Suanluang, Suanluang, Bangkok 10250, THailand ?????°§ ®§????????? °§?????°Ï ®§??????? °ß????? ®§??°§?? 88 ??°Ë?????????? ???? 3 ?????????®§??? 57/1 (??®§?????2) ®¢??°Ï??????°Ï ®§????????°Ï ???°Ï®§°§?? 10250 Phone: 02-3704900 (auto 10 lines) Fax: 02-3704920-21 Email : admin@ptsc.co.th, sales@ptsc.co.th Tax ID : 0105538110825www.ptsc.co.th