サウンドの方への骋骋闯绍介

1 like1,241 views

SIG-Audio#2でのサウンドの方への骋骋闯绍介スライドです。 http://www.adx2le.com/

1 of 11

Download to read offline

Ad

Recommended

SIG-Audio#13 GDC2016オーディオ報告会「サウンド向上のため最新技術を使わずとも今すぐできること」

SIG-Audio#13 GDC2016オーディオ報告会「サウンド向上のため最新技術を使わずとも今すぐできること」Takafumi Inamori

?

SIG-Audio#13 GDC2016オーディオ報告会「サウンド向上のため最新技術を使わずとも今すぐできること」SIG-Audio#14 GDC2017オーディオ報告会 「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別...

SIG-Audio#14 GDC2017オーディオ報告会 「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別...IGDA Japan SIG-Audio

?

SIG-Audio#14 GDC2017オーディオ報告会

「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別に厳選し各セッションを振り返る~」SIG-Audio#13 GDC2016オーディオ報告会「ちょっくらサンフランシスコに行って、GDCでBEATWIZを展示してきた件」

SIG-Audio#13 GDC2016オーディオ報告会「ちょっくらサンフランシスコに行って、GDCでBEATWIZを展示してきた件」IGDA Japan SIG-Audio

?

SIG-Audio#13 GDC2016オーディオ報告会「ちょっくらサンフランシスコに行って、GDCでBEATWIZを展示してきた件」SIG-Audio#17 GDC2019オーディオ報告会 「より没入感のある音響ユーザー体験のために」

SIG-Audio#17 GDC2019オーディオ報告会 「より没入感のある音響ユーザー体験のために」IGDA Japan SIG-Audio

?

SIG-Audio#17 GDC2019オーディオ報告会 「より没入感のある音響ユーザー体験のために」SIG-Audio#13 GDC2016オーディオ報告会「日本語翻訳されないサウンドデザイン技術を求めて」

SIG-Audio#13 GDC2016オーディオ報告会「日本語翻訳されないサウンドデザイン技術を求めて」IGDA Japan SIG-Audio

?

SIG-Audio#13 GDC2016オーディオ報告会「日本語翻訳されないサウンドデザイン技術を求めて」SIG-Audio#15 GDC2018オーディオ報告会「没入感あるサウンド制作への取り組み」

SIG-Audio#15 GDC2018オーディオ報告会「没入感あるサウンド制作への取り組み」IGDA Japan SIG-Audio

?

SIG-Audio#15 GDC2018オーディオ報告会

「没入感あるサウンド制作への取り組み」

20160625 Google I/O Extended 報告会 Fukuoka 2016 "Audio and Music"

20160625 Google I/O Extended 報告会 Fukuoka 2016 "Audio and Music"Yukio TADA

?

2016-06-25

Google I/O Extended 報告会 Fukuoka 2016 での講演資料

"Audio and Music"Ocean spray managed tms

Ocean spray managed tmspurplestains88

?

Ocean Spray moved to a Managed TMS solution from TMC to improve key performance metrics like on-time delivery rates and freight costs. TMC's solution provides TMS software, process engineering expertise, and dedicated users to help optimize Ocean Spray's transportation network. This resulted in on-time deliveries increasing to 95% from 85% and carriers accepting over 75% of loads, positively impacting freight costs and Ocean Spray's supply chain decision making.Presentation1

Presentation1Saikat Bardhan

?

1. The document discusses the ABC (activity-based costing) approach and its relationship to just-in-time (JIT) production and total quality management (TQM).

2. It also discusses delays in taking action based on ABC analysis and the need for an explicit plan to transition from ABC analysis to managerial action.

3. Finally, it discusses when ABC-type cost information may be needed, focusing on reducing variation and lead time rather than implementation of ABC itself.Tms Toyota Scion Adp 09 24 2009 V4

Tms Toyota Scion Adp 09 24 2009 V4Ralph Paglia

?

The document summarizes discussions from a meeting between ADP/TMS and Toyota about improving ecommerce, digital marketing, and dealer performance. Key points discussed include:

- ADP/TMS presented dashboard solutions and best practices to streamline operations and increase digital advertising.

- Business intelligence tools from Toyota's Performance Group can extract and analyze data from all dealer management systems to identify performance drivers and provide daily updates, guided scenarios, and training.

- Recommendations were made around improving the quality of client experiences with internet leads to increase closing rates, such as ensuring a timely first response, ongoing engagement, and follow-up over 60 and 90 days.

- Metrics around lead response time, details, resources,The Science of Lean Transformation by Daniel T Jones

The Science of Lean Transformation by Daniel T JonesLean Enterprise Academy

?

This document discusses the evolution of management approaches from scientific management to modern lean management. [1] It outlines how Toyota created a new synthesis of rigorous strategy formulation and continuous improvement through practices like PDCA. [2] A lean management system is proposed that focuses on direction, value streams, enabling projects, and using the scientific approach. [3] The goal of any lean transformation should be developing capabilities to continuously solve new problems and sustain improvements over time.サウンドゲームジャムとは?

サウンドゲームジャムとは?Takashi Tanaka

?

サウンドゲームジャムとは?

GCS2013で行われたサウンドゲームジャムのコミュニティの報告です。

http://www.inside-games.jp/article/2013/04/24/65878.htmlMore Related Content

What's hot (16)

SIG-Audio#14 GDC2017オーディオ報告会 「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別...

SIG-Audio#14 GDC2017オーディオ報告会 「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別...IGDA Japan SIG-Audio

?

SIG-Audio#14 GDC2017オーディオ報告会

「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別に厳選し各セッションを振り返る~」SIG-Audio#13 GDC2016オーディオ報告会「ちょっくらサンフランシスコに行って、GDCでBEATWIZを展示してきた件」

SIG-Audio#13 GDC2016オーディオ報告会「ちょっくらサンフランシスコに行って、GDCでBEATWIZを展示してきた件」IGDA Japan SIG-Audio

?

SIG-Audio#13 GDC2016オーディオ報告会「ちょっくらサンフランシスコに行って、GDCでBEATWIZを展示してきた件」SIG-Audio#17 GDC2019オーディオ報告会 「より没入感のある音響ユーザー体験のために」

SIG-Audio#17 GDC2019オーディオ報告会 「より没入感のある音響ユーザー体験のために」IGDA Japan SIG-Audio

?

SIG-Audio#17 GDC2019オーディオ報告会 「より没入感のある音響ユーザー体験のために」SIG-Audio#13 GDC2016オーディオ報告会「日本語翻訳されないサウンドデザイン技術を求めて」

SIG-Audio#13 GDC2016オーディオ報告会「日本語翻訳されないサウンドデザイン技術を求めて」IGDA Japan SIG-Audio

?

SIG-Audio#13 GDC2016オーディオ報告会「日本語翻訳されないサウンドデザイン技術を求めて」SIG-Audio#15 GDC2018オーディオ報告会「没入感あるサウンド制作への取り組み」

SIG-Audio#15 GDC2018オーディオ報告会「没入感あるサウンド制作への取り組み」IGDA Japan SIG-Audio

?

SIG-Audio#15 GDC2018オーディオ報告会

「没入感あるサウンド制作への取り組み」

20160625 Google I/O Extended 報告会 Fukuoka 2016 "Audio and Music"

20160625 Google I/O Extended 報告会 Fukuoka 2016 "Audio and Music"Yukio TADA

?

2016-06-25

Google I/O Extended 報告会 Fukuoka 2016 での講演資料

"Audio and Music"SIG-Audio#14 GDC2017オーディオ報告会 「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別...

SIG-Audio#14 GDC2017オーディオ報告会 「海外クリエーターから学んだサウンド開発レベルのスレッショルドライン~GDC2017をジャンル別...IGDA Japan SIG-Audio

?

Viewers also liked (6)

Ocean spray managed tms

Ocean spray managed tmspurplestains88

?

Ocean Spray moved to a Managed TMS solution from TMC to improve key performance metrics like on-time delivery rates and freight costs. TMC's solution provides TMS software, process engineering expertise, and dedicated users to help optimize Ocean Spray's transportation network. This resulted in on-time deliveries increasing to 95% from 85% and carriers accepting over 75% of loads, positively impacting freight costs and Ocean Spray's supply chain decision making.Presentation1

Presentation1Saikat Bardhan

?

1. The document discusses the ABC (activity-based costing) approach and its relationship to just-in-time (JIT) production and total quality management (TQM).

2. It also discusses delays in taking action based on ABC analysis and the need for an explicit plan to transition from ABC analysis to managerial action.

3. Finally, it discusses when ABC-type cost information may be needed, focusing on reducing variation and lead time rather than implementation of ABC itself.Tms Toyota Scion Adp 09 24 2009 V4

Tms Toyota Scion Adp 09 24 2009 V4Ralph Paglia

?

The document summarizes discussions from a meeting between ADP/TMS and Toyota about improving ecommerce, digital marketing, and dealer performance. Key points discussed include:

- ADP/TMS presented dashboard solutions and best practices to streamline operations and increase digital advertising.

- Business intelligence tools from Toyota's Performance Group can extract and analyze data from all dealer management systems to identify performance drivers and provide daily updates, guided scenarios, and training.

- Recommendations were made around improving the quality of client experiences with internet leads to increase closing rates, such as ensuring a timely first response, ongoing engagement, and follow-up over 60 and 90 days.

- Metrics around lead response time, details, resources,The Science of Lean Transformation by Daniel T Jones

The Science of Lean Transformation by Daniel T JonesLean Enterprise Academy

?

This document discusses the evolution of management approaches from scientific management to modern lean management. [1] It outlines how Toyota created a new synthesis of rigorous strategy formulation and continuous improvement through practices like PDCA. [2] A lean management system is proposed that focuses on direction, value streams, enabling projects, and using the scientific approach. [3] The goal of any lean transformation should be developing capabilities to continuously solve new problems and sustain improvements over time.サウンドゲームジャムとは?

サウンドゲームジャムとは?Takashi Tanaka

?

サウンドゲームジャムとは?

GCS2013で行われたサウンドゲームジャムのコミュニティの報告です。

http://www.inside-games.jp/article/2013/04/24/65878.htmlAd

Similar to サウンドの方への骋骋闯绍介 (20)

Experimental Gameplay Workshop 20年をふりかえる

Experimental Gameplay Workshop 20年をふりかえるsyamane

?

Experimental Gameplay Workshop 20年をふりかえる

IGDA日本「オンライン交流会&ライトニングトーク」2022年4月28日 LT2

ユーザーに爱されるソフトを作りたい!!

ユーザーに爱されるソフトを作りたい!!hiyohiyo

?

約16年間に渡るフリーソフト/オープンソース開発で培った愛されるソフトに育てるノウハウを実体験を交えながら紹介させていただきます。

めとべや東京 #6 における発表資料です。[Unite 2016 Tokyo]Unityを使った個人ゲーム開発における「収益化」の現状と未来

[Unite 2016 Tokyo]Unityを使った個人ゲーム開発における「収益化」の現状と未来Takaaki Ichijo

?

Unite 2016 Tokyo登壇の資料です。

※ https://japan.unity3d.com/unite/unite2016/files/DAY2_1700_Room2_IchijoTakaaki.pdf が消えていたので自分でアップロードしました。Ad

More from Takashi Tanaka (10)

第七回サウンドゲームジャム.辫辫迟虫

第七回サウンドゲームジャム.辫辫迟虫Takashi Tanaka

?

第七回サウンドゲームジャム

のスライドになります

https://effectorhack.connpass.com/event/248491/痴搁近未来サウンドデザイン

痴搁近未来サウンドデザインTakashi Tanaka

?

2021/08/26、CEDEC2021にて行われた発表の講演資料です。

SND

痴搁近未来サウンドデザイン

田中 孝

MyDearest株式会社

#アルトデウスBC #CEDEC2021

https://cedec.cesa.or.jp/2021/session/detail/s6053ec25ede4d第5回サウント?ケ?ームシ?ャム

第5回サウント?ケ?ームシ?ャムTakashi Tanaka

?

20160416 サウント?ケ?ームシ?ャム

http://effectorhack.connpass.com/event/27404/ #soundgamejamインタラクティブミュージックの歴史ちゃーりー感 2013-12-15

インタラクティブミュージックの歴史ちゃーりー感 2013-12-15 Takashi Tanaka

?

2013-12-15 インタラクティブミュージック勉強会 #4

インタラクティブミュージックの歴史ちゃーりー感

(間違い、勘違いもあるかと思いますので取り扱いに注意)ネコでもわかるインタラクティブサウンド20130706

ネコでもわかるインタラクティブサウンド20130706Takashi Tanaka

?

2013-07-06福島ゲームジャム事前セミナーの資料です。

サウンド制作の為の波形編集ソフト「Audacity」の使い方とインタラクティブサウンドの作り方をADX2LEを使って紹介します。

本日7/6ADX2LEのワークショップで使うデータ

http://www.adx2le.com/event/fgj2013.htmlADX2LE GGJ13向けワークショップ

ADX2LE GGJ13向けワークショップTakashi Tanaka

?

GlobalGameJam2013直前に行われたADX2LEワークショップの配布資料をまとめたものです。

ADX2LEの導入方法、Unityとの連携動作の詳細、エラーで困った場合や、インゲームプレビューで困った場合など、

何をするものなのかなどの一通りの解説となっています。

サイト→ http://www.adx2le.com/

ウィキ→ http://www53.atwiki.jp/soundtasukeai/pages/22.html第8回Unity勉強会 Unityサウンド入門編 と サウンドワークショップ事例 Tech buzz8 Unity Study 20120927 tanaka

第8回Unity勉強会 Unityサウンド入門編 と サウンドワークショップ事例 Tech buzz8 Unity Study 20120927 tanakaTakashi Tanaka

?

第8回Unity勉強会 Unityサウンド入門編 と サウンドワークショップ事例CEDEC2012 sound workshop

CEDEC2012 sound workshopTakashi Tanaka

?

CEDEC2012で行われた【ゲームに音を付けるワークショップ】の資料です。

関連データなどはこちら→http://www.adx2le.com/workshop_archive.htmlサウンドの方への骋骋闯绍介

- 1. サウンドの方への GGJ2013の紹介 2013-01-18 田中孝 @SIG-Audio#2 1

- 2. 骋骋闯とは? 2

- 3. 骋骋闯とは? ? Global Game Jamという2日半という短 期間数人チームでゲームを作るイベント。 ? 世界中で同時に同じテーマでゲームが作ら れる、世界最大のゲーム開発イベント。 http://globalgamejam.org/ 3

- 5. GGJ2013サウンドの方 も募集しています ? サウンド参加者が不足しています。 ? モテます。 ? 好きな音をつけられます。 5

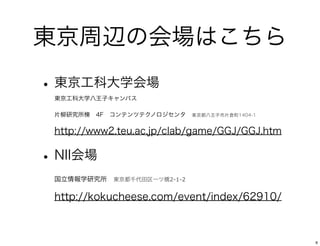

- 6. 東京周辺の会場はこちら ? 東京工科大学会場 東京工科大学八王子キャンパス? 片柳研究所棟?4F?コンテンツテクノロジセンタ?東京都八王子市片倉町1404-1 http://www2.teu.ac.jp/clab/game/GGJ/GGJ.htm ? NII会場 国立情報学研究所?東京都千代田区一ツ橋2-1-2 http://kokucheese.com/event/index/62910/ 6

- 8. NII会場 ? 専用ノベル系エンジ ン「アトラスX」に て開発 8

- 9. 登録の仕方 ? GGJ13の本家サイト(英語)の登録と ? 各種会場の登録の2つ必要です。 ? なお、サウンド系ミドルウェアの試用 UnityProライセンスの試用版などが提供され ます。(たぶん) 音声合成のAITalkやゲームサウンドオーサリン グツールを含むADX2 LEも使えます。 9

- 10. GGJ期間 ? 1/25(金)夕方 1/27(日)夕方 ? チームの了承が得られれば途中帰宅も可 ? 見学も歓迎 10

- 11. 持ち物 ? 開発ノートPC(デスクトップとか電源 確保で無理な場合もあります) ? 楽器(インターフェース?ソフト) ? 相手を思いやる心 ? とにかく楽しむ心 11