1 of 27

Downloaded 12 times

Ad

Recommended

Ceramic fibers

Ceramic fibersFarhan ullah baig

?

This document discusses ceramic fibers, including their production, classification, properties, and uses. Ceramic fibers are man-made heat resistant fibers produced through direct melt spinning or indirect chemical vapor deposition processes. They are classified based on their chemical composition as oxide fibers like silica and alumina or non-oxide fibers like silicon carbide. Ceramic fibers have properties of hardness, low density, high compressive strength, and excellent thermal resistance at high temperatures. Their main uses are as high temperature insulation and reinforcement in metal and ceramic matrix composites.How to use ketamine fearlessly for all its indications smacc 2015 no builds

How to use ketamine fearlessly for all its indications smacc 2015 no buildsSMACC Conference

?

The document discusses the use of ketamine for various medical indications, emphasizing its safety and efficacy in procedural sedation and analgesia. It highlights the effects of ketamine on the body and brain, while addressing common concerns and contraindications associated with its use. The document also outlines specific dosages and scenarios for ketamine administration, particularly for patients with respiratory issues or chronic pain.Day In the Life Of (DILO) - How To Do it - Practical guide

Day In the Life Of (DILO) - How To Do it - Practical guideRichard Fontaine

?

This document provides guidance on performing a Day in the Life Of (DILO) job observation. It outlines eight steps: 1) validating observations are possible; 2) defining objectives; 3) determining scope of observations; 4) customizing templates; 5) preparing for observations; 6) executing observations; 7) reporting; and 8) analyzing for value-add opportunities. Key recommendations include involving unions early, focusing observations based on objectives, and preparing thoroughly including understanding the job in advance. The level of detail in scoping and executing observations should match the objective of gaining qualitative or quantitative insights.Gemba Kaizen for lean manufacturing chap2 | kaizen collection of cases | lea...

Gemba Kaizen for lean manufacturing chap2 | kaizen collection of cases | lea...博行 門眞

?

The document discusses various Kaizen examples related to lean manufacturing, emphasizing the importance of continuous improvement in work processes. Key illustrations include approaches to optimize boxing practices, reduce airborne dust in machining, and enhance visual management for preventing errors. Each example highlights problem identification, suggestions for improvement, and the rationale behind those suggestions.5S NL deel 1.pptx

5S NL deel 1.pptxBertTeeuwen1

?

Wat is 5S?

In het kort uitgelegd in drie delen.

Het doel van

5S is niet opruimen

5S is cre?ren van flow.

Wegnemen van verliezen5S Implementation Presentation

5S Implementation Presentation Pranav B. Gujjar

?

The document provides details on a presentation about implementing 5S. The objectives are to improve the work environment, support safe and efficient work practices, and establish an auditing system. The presentation covers defining 5S, the 5S terminology and benefits, the red tag process for identifying unneeded items, explaining each of the 5 S's, best practices, color coding standards, and a checklist. Implementation requires identifying a leader, training a team, sorting needed and unneeded items, properly storing and labeling everything, establishing cleaning and inspection standards, and sustaining the system through ongoing meetings and recognition.The Muda, Mura and Muri of DevOps

The Muda, Mura and Muri of DevOpsSanjeev Sharma

?

The document discusses improving flow in DevOps delivery pipelines by addressing three key concepts: muda (waste), mura (unevenness), and muri (overburden). It emphasizes continuous feedback for improvement and the importance of modernizing architectures to enhance efficiency. Additionally, it advocates for a collaborative team approach where all members share responsibility for delivering business value.Reduce SMT Changeover Time

Reduce SMT Changeover TimeDamian Denis

?

This document outlines a plan to reduce SMT changeover time at Bose from 30 minutes to 18 minutes (a 40% reduction). It involves a 12-step process to define the problem, analyze root causes, identify countermeasures, implement solutions, and monitor results. Key countermeasures selected include training on a "F1 mindset", moving tasks like material scanning and setup preparation offline, and ensuring gantry tables are ready ahead of changeovers. Initial results showed the new changeover time of 18 minutes was achieved. Ongoing monitoring and standardization across lines is planned.Presentation - introduction to 5S

Presentation - introduction to 5SJan Sabat

?

The document discusses the 5S methodology for organizing the workplace. It introduces the 5S concepts of sorting, straightening, shining, standardizing and sustaining an organized work environment. Examples are given showing the benefits of applying 5S principles by removing unnecessary items, clearly identifying what belongs and maintaining an orderly workspace. This allows for safer, more efficient work without wasted time searching for needed items. The document suggests implementing 5S is essential for a productive workplace and competitive company by establishing strong organizational foundations.flexible manufacturing systems

flexible manufacturing systemsShivam Joshi

?

A flexible manufacturing system (FMS) is an automated machine cell consisting of a group of processing workstations like CNC machine tools interconnected by an automated material handling and storage system and controlled by a distributed computer system. FMS allows manufacturers to produce a variety of different part styles simultaneously and adjust production mix in response to changing demand while maintaining good quality and low costs. It transfers workpieces between machining stations using automated equipment like conveyors.5 s ppt

5 s pptAmar Raveendran

?

5S is a workplace organization methodology consisting of five Japanese words - sorting, straightening, systematic cleaning, standardizing, and sustaining. The steps involve eliminating unnecessary items, clearly labeling storage areas, cleaning workspaces daily, making all workstations identical, and maintaining standards over time. Implementing 5S improves organizational efficiency, reduces waste, cuts frustration, and improves speed, quality, safety and the work environment. The objectives are increased productivity, safety, and reduced waste while gaining worker commitment.Step-By-Step Approach in implementing 5S in your factory

Step-By-Step Approach in implementing 5S in your factoryHash Management Services LLP

?

This document outlines a step-by-step approach to implementing the 5S methodology in workplaces, focusing on maintaining cleanliness, organization, and continual improvement. It details the five steps: Sort, Set in Order, Shine, Standardize, and Sustain, along with specific actions for each step to engage employees and enhance workplace culture. Additionally, it emphasizes the importance of management commitment, regular audits, and employee training for successful and sustained implementation.Dojo training

Dojo trainingvadivelan_k

?

This document provides an overview of Dojo, an open source JavaScript toolkit. It discusses the core components of Dojo including the core libraries for DOM handling, CSS handling, and JavaScript enhancements. It also describes Dijit, which provides accessible widgets, and DojoX, which contains experimental modules. The core provides basic functions for AJAX, events, animation and more. Dijit offers predefined widgets and mechanisms for creating custom widgets. DojoX extends the core functionality with additional widgets, behaviors, stores and other modules.Creating World Class Organization Through 5S and Visual Management @ 3rd Ann...

Creating World Class Organization Through 5S and Visual Management @ 3rd Ann...ADD VALUE CONSULTING Inc

?

The document discusses the implementation of 5S and visual management techniques to create world-class organizations. It describes the 5S methodology as a 5-step process to reduce waste, including sorting, systematic arrangement, spic and span, standardization, and self-discipline. The steps involve organizing the workspace and establishing visual controls. Implementing 5S provides benefits such as improved productivity, quality and safety. It also reduces costs and waste. The presentation provides examples of implementing 5S and recommends defining the implementation scope, collecting baseline data, and using data to guide the process.Workplace safety

Workplace safety5S BALAMURUGAN

?

Workplace safety is important. Keep workplaces clean, organized and free of obstructions. Clean up spills immediately. Cover holes and pits. Ensure good lighting, ventilation and sanitation. Wear appropriate protective gear like safety shoes and face shields. Know how to use emergency equipment and report electrical or other hazards immediately. Only authorized personnel should work on electrical equipment. Handle tools and materials safely and report defective equipment. Store and handle flammable materials carefully. Know first aid procedures and get treatment promptly for any injuries. Observe all safety signs and follow proper procedures for hazardous equipment or jobs.Toyota Raymond Kaizen Presentation 16 June 2008

Toyota Raymond Kaizen Presentation 16 June 2008Mark Dawson

?

The document summarizes the lessons learned by Uniparts Olsen Inc. from implementing Kaizen practices facilitated by Toyota. It discusses how previous implementation of lean tools fell short of targets and were not sustained. With guidance from Toyota, Uniparts adopted Toyota Production System philosophies of management involvement in gemba, standardization, visual management, and continuous improvement. This resulted in improved metrics like 70% scrap reduction and led management to realize that success requires a long-term commitment to endless improvement through small gains.5S,Safety Slogans in Tamil & English

5S,Safety Slogans in Tamil & English5S BALAMURUGAN

?

This document provides safety slogans in both Tamil and English languages to promote 5S principles and safety in the workplace. It contains 60 pages with 60 different slogans translated between the two languages. A link is provided to download the full document containing all the bilingual safety slogans.Industry 4.0 and 3d printer

Industry 4.0 and 3d printerMEB L?SE ??RETMENLER?

?

This document discusses the history of industrial revolutions and how 3D printing fits within the context of the current fourth industrial revolution. It outlines key inventions from the first three industrial revolutions including the steam engine, airplane, and computer. The fourth industrial revolution is characterized by unprecedented developments in areas like genetics, nanotechnology, and artificial intelligence. 3D printing is described as a technology that builds 3D objects from digital models using materials like plastic that harden after being heated and deposited layer by layer.Polymer innovation presentation

Polymer innovation presentationWMG, University of Warwick

?

The document summarizes the work of the Polymer Innovation Team at the Institute for Innovation in Polymer Science and Sustainability (IIPSI). The team includes experts in additive manufacturing, composites, polymer processing, and recycling. They work with companies to develop new polymer products and processes through access to state-of-the-art facilities and expertise in areas like prototyping, low volume manufacturing, adding functionality, and recycling. Their goal is to help companies commercialize innovative polymer technologies.5厂活动とは? 断捨离のすすめ

5厂活动とは? 断捨离のすすめ博行 門眞

?

工場での断捨離の具体的すすめ方。

「整理」「整頓」「清掃」「清潔」「しつけ」の頭文字をとって5Sという。

関連記事:改善ネット

https://kaizen1.netCnc technology

Cnc technology ahirehemant

?

The document discusses computer numerical control (CNC) technology. It provides a brief history of CNC development from the first numerically controlled machine commissioned by the US Air Force in 1949. It defines CNC as using a microcomputer to store machine instructions and control logic. The document outlines common CNC applications in machining like milling and turning, as well as forming processes. It also discusses the typical components of a CNC system and provides examples of industries that utilize CNC manufacturing.TPM Basics

TPM Basics5S BALAMURUGAN

?

Total productive maintenance (TPM) is a comprehensive approach focused on maximizing equipment effectiveness and achieving perfect production through the active participation of all employees. It comprises several pillars including focused improvement, autonomous maintenance, planned maintenance, quality maintenance, education & training, early equipment management, health & safety, and office TPM. The ultimate goal of TPM is to enhance overall equipment efficiency, eliminate losses, and create a sustainable workplace.Learning to see (VSM)

Learning to see (VSM)Mohamed Effat

?

The document discusses value stream mapping (VSM), which is a tool used to analyze and visualize the flow of materials and information required to bring a product to a customer. It describes the key aspects of creating a current state map to document the existing process, as well as developing a future state map to design an improved lean process. Some of the main points covered include establishing continuous flow, supermarkets with pull systems, leveling production to match takt time, and implementing changes through a value stream plan. VSM provides a way to analyze processes, identify waste, and develop plans to create efficient lean material and information flows.优れた研究提案书の书き方

优れた研究提案书の书き方Masanori Kado

?

https://www.microsoft.com/en-us/research/academic-program/how-to-write-a-great-research-proposal/优れた研究论文の书き方

优れた研究论文の书き方Masanori Kado

?

狠狠撸shareは再アップロード不可なのでerrataはコチラ:

p16:Structure(Conference Paper) →構成(カンファレンスペーパー)

p28:Structure → 構成

p47:マン → マージン

オリジナル:

https://www.microsoft.com/en-us/research/academic-program/write-great-research-paper/

旧版の翻訳(内容はほとんど同じです):

/kdmsnr/writing-a-paper-seven-suggestions

Tokyo-Tech 2017 EDP-A #3 Prototype and Test

Tokyo-Tech 2017 EDP-A #3 Prototype and TestMasanori Kado

?

This document outlines the process for prototyping and testing in Engineering Design Project A. It discusses that the goal of the class is to prepare students for more advanced design projects through hands-on prototyping and testing. It describes the different stages of prototyping from initial concept prototypes to functional prototypes. Students will create functional prototypes, test them with users at least 5 times, and iteratively improve the prototypes based on user feedback. Testing involves observing how users interact with prototypes without instruction and asking targeted questions. The document emphasizes learning through repeated testing and reflection on the process.Tokyo-Tech 2017 EDP-A #2 Ideate & Prototype

Tokyo-Tech 2017 EDP-A #2 Ideate & PrototypeMasanori Kado

?

This document outlines an engineering design project class that skips the problem definition step and focuses on ideation and prototyping. It provides instructions for students to observe situations, brainstorm ideas, and create low-fidelity prototypes. Students are encouraged to think creatively and come up with unconventional ideas. They use a SIPOC model to map out the elements of their prototype concepts. The goal is to generate innovative solutions and get students building tangible prototypes early in the process through an experimental "think-while-prototyping" approach.Tokyo-Tech 2017 EDP-A #1 Team Building

Tokyo-Tech 2017 EDP-A #1 Team BuildingMasanori Kado

?

This document outlines the agenda and activities for a team building exercise. The exercise involves engineering design students drawing pictures of their team members, identifying their strengths, creating hypothetical business plans by combining members' strengths, and discussing what allows some teams to create "WOW" products while others only receive "Thank you" feedback. The goal is for teams to learn how to exploit members' strengths and work together effectively to achieve psychological safety, an important factor in high performing teams. Students are encouraged to share ideas and discuss lessons learned.More Related Content

What's hot (16)

Reduce SMT Changeover Time

Reduce SMT Changeover TimeDamian Denis

?

This document outlines a plan to reduce SMT changeover time at Bose from 30 minutes to 18 minutes (a 40% reduction). It involves a 12-step process to define the problem, analyze root causes, identify countermeasures, implement solutions, and monitor results. Key countermeasures selected include training on a "F1 mindset", moving tasks like material scanning and setup preparation offline, and ensuring gantry tables are ready ahead of changeovers. Initial results showed the new changeover time of 18 minutes was achieved. Ongoing monitoring and standardization across lines is planned.Presentation - introduction to 5S

Presentation - introduction to 5SJan Sabat

?

The document discusses the 5S methodology for organizing the workplace. It introduces the 5S concepts of sorting, straightening, shining, standardizing and sustaining an organized work environment. Examples are given showing the benefits of applying 5S principles by removing unnecessary items, clearly identifying what belongs and maintaining an orderly workspace. This allows for safer, more efficient work without wasted time searching for needed items. The document suggests implementing 5S is essential for a productive workplace and competitive company by establishing strong organizational foundations.flexible manufacturing systems

flexible manufacturing systemsShivam Joshi

?

A flexible manufacturing system (FMS) is an automated machine cell consisting of a group of processing workstations like CNC machine tools interconnected by an automated material handling and storage system and controlled by a distributed computer system. FMS allows manufacturers to produce a variety of different part styles simultaneously and adjust production mix in response to changing demand while maintaining good quality and low costs. It transfers workpieces between machining stations using automated equipment like conveyors.5 s ppt

5 s pptAmar Raveendran

?

5S is a workplace organization methodology consisting of five Japanese words - sorting, straightening, systematic cleaning, standardizing, and sustaining. The steps involve eliminating unnecessary items, clearly labeling storage areas, cleaning workspaces daily, making all workstations identical, and maintaining standards over time. Implementing 5S improves organizational efficiency, reduces waste, cuts frustration, and improves speed, quality, safety and the work environment. The objectives are increased productivity, safety, and reduced waste while gaining worker commitment.Step-By-Step Approach in implementing 5S in your factory

Step-By-Step Approach in implementing 5S in your factoryHash Management Services LLP

?

This document outlines a step-by-step approach to implementing the 5S methodology in workplaces, focusing on maintaining cleanliness, organization, and continual improvement. It details the five steps: Sort, Set in Order, Shine, Standardize, and Sustain, along with specific actions for each step to engage employees and enhance workplace culture. Additionally, it emphasizes the importance of management commitment, regular audits, and employee training for successful and sustained implementation.Dojo training

Dojo trainingvadivelan_k

?

This document provides an overview of Dojo, an open source JavaScript toolkit. It discusses the core components of Dojo including the core libraries for DOM handling, CSS handling, and JavaScript enhancements. It also describes Dijit, which provides accessible widgets, and DojoX, which contains experimental modules. The core provides basic functions for AJAX, events, animation and more. Dijit offers predefined widgets and mechanisms for creating custom widgets. DojoX extends the core functionality with additional widgets, behaviors, stores and other modules.Creating World Class Organization Through 5S and Visual Management @ 3rd Ann...

Creating World Class Organization Through 5S and Visual Management @ 3rd Ann...ADD VALUE CONSULTING Inc

?

The document discusses the implementation of 5S and visual management techniques to create world-class organizations. It describes the 5S methodology as a 5-step process to reduce waste, including sorting, systematic arrangement, spic and span, standardization, and self-discipline. The steps involve organizing the workspace and establishing visual controls. Implementing 5S provides benefits such as improved productivity, quality and safety. It also reduces costs and waste. The presentation provides examples of implementing 5S and recommends defining the implementation scope, collecting baseline data, and using data to guide the process.Workplace safety

Workplace safety5S BALAMURUGAN

?

Workplace safety is important. Keep workplaces clean, organized and free of obstructions. Clean up spills immediately. Cover holes and pits. Ensure good lighting, ventilation and sanitation. Wear appropriate protective gear like safety shoes and face shields. Know how to use emergency equipment and report electrical or other hazards immediately. Only authorized personnel should work on electrical equipment. Handle tools and materials safely and report defective equipment. Store and handle flammable materials carefully. Know first aid procedures and get treatment promptly for any injuries. Observe all safety signs and follow proper procedures for hazardous equipment or jobs.Toyota Raymond Kaizen Presentation 16 June 2008

Toyota Raymond Kaizen Presentation 16 June 2008Mark Dawson

?

The document summarizes the lessons learned by Uniparts Olsen Inc. from implementing Kaizen practices facilitated by Toyota. It discusses how previous implementation of lean tools fell short of targets and were not sustained. With guidance from Toyota, Uniparts adopted Toyota Production System philosophies of management involvement in gemba, standardization, visual management, and continuous improvement. This resulted in improved metrics like 70% scrap reduction and led management to realize that success requires a long-term commitment to endless improvement through small gains.5S,Safety Slogans in Tamil & English

5S,Safety Slogans in Tamil & English5S BALAMURUGAN

?

This document provides safety slogans in both Tamil and English languages to promote 5S principles and safety in the workplace. It contains 60 pages with 60 different slogans translated between the two languages. A link is provided to download the full document containing all the bilingual safety slogans.Industry 4.0 and 3d printer

Industry 4.0 and 3d printerMEB L?SE ??RETMENLER?

?

This document discusses the history of industrial revolutions and how 3D printing fits within the context of the current fourth industrial revolution. It outlines key inventions from the first three industrial revolutions including the steam engine, airplane, and computer. The fourth industrial revolution is characterized by unprecedented developments in areas like genetics, nanotechnology, and artificial intelligence. 3D printing is described as a technology that builds 3D objects from digital models using materials like plastic that harden after being heated and deposited layer by layer.Polymer innovation presentation

Polymer innovation presentationWMG, University of Warwick

?

The document summarizes the work of the Polymer Innovation Team at the Institute for Innovation in Polymer Science and Sustainability (IIPSI). The team includes experts in additive manufacturing, composites, polymer processing, and recycling. They work with companies to develop new polymer products and processes through access to state-of-the-art facilities and expertise in areas like prototyping, low volume manufacturing, adding functionality, and recycling. Their goal is to help companies commercialize innovative polymer technologies.5厂活动とは? 断捨离のすすめ

5厂活动とは? 断捨离のすすめ博行 門眞

?

工場での断捨離の具体的すすめ方。

「整理」「整頓」「清掃」「清潔」「しつけ」の頭文字をとって5Sという。

関連記事:改善ネット

https://kaizen1.netCnc technology

Cnc technology ahirehemant

?

The document discusses computer numerical control (CNC) technology. It provides a brief history of CNC development from the first numerically controlled machine commissioned by the US Air Force in 1949. It defines CNC as using a microcomputer to store machine instructions and control logic. The document outlines common CNC applications in machining like milling and turning, as well as forming processes. It also discusses the typical components of a CNC system and provides examples of industries that utilize CNC manufacturing.TPM Basics

TPM Basics5S BALAMURUGAN

?

Total productive maintenance (TPM) is a comprehensive approach focused on maximizing equipment effectiveness and achieving perfect production through the active participation of all employees. It comprises several pillars including focused improvement, autonomous maintenance, planned maintenance, quality maintenance, education & training, early equipment management, health & safety, and office TPM. The ultimate goal of TPM is to enhance overall equipment efficiency, eliminate losses, and create a sustainable workplace.Learning to see (VSM)

Learning to see (VSM)Mohamed Effat

?

The document discusses value stream mapping (VSM), which is a tool used to analyze and visualize the flow of materials and information required to bring a product to a customer. It describes the key aspects of creating a current state map to document the existing process, as well as developing a future state map to design an improved lean process. Some of the main points covered include establishing continuous flow, supermarkets with pull systems, leveling production to match takt time, and implementing changes through a value stream plan. VSM provides a way to analyze processes, identify waste, and develop plans to create efficient lean material and information flows.Creating World Class Organization Through 5S and Visual Management @ 3rd Ann...

Creating World Class Organization Through 5S and Visual Management @ 3rd Ann...ADD VALUE CONSULTING Inc

?

More from Masanori Kado (20)

优れた研究提案书の书き方

优れた研究提案书の书き方Masanori Kado

?

https://www.microsoft.com/en-us/research/academic-program/how-to-write-a-great-research-proposal/优れた研究论文の书き方

优れた研究论文の书き方Masanori Kado

?

狠狠撸shareは再アップロード不可なのでerrataはコチラ:

p16:Structure(Conference Paper) →構成(カンファレンスペーパー)

p28:Structure → 構成

p47:マン → マージン

オリジナル:

https://www.microsoft.com/en-us/research/academic-program/write-great-research-paper/

旧版の翻訳(内容はほとんど同じです):

/kdmsnr/writing-a-paper-seven-suggestions

Tokyo-Tech 2017 EDP-A #3 Prototype and Test

Tokyo-Tech 2017 EDP-A #3 Prototype and TestMasanori Kado

?

This document outlines the process for prototyping and testing in Engineering Design Project A. It discusses that the goal of the class is to prepare students for more advanced design projects through hands-on prototyping and testing. It describes the different stages of prototyping from initial concept prototypes to functional prototypes. Students will create functional prototypes, test them with users at least 5 times, and iteratively improve the prototypes based on user feedback. Testing involves observing how users interact with prototypes without instruction and asking targeted questions. The document emphasizes learning through repeated testing and reflection on the process.Tokyo-Tech 2017 EDP-A #2 Ideate & Prototype

Tokyo-Tech 2017 EDP-A #2 Ideate & PrototypeMasanori Kado

?

This document outlines an engineering design project class that skips the problem definition step and focuses on ideation and prototyping. It provides instructions for students to observe situations, brainstorm ideas, and create low-fidelity prototypes. Students are encouraged to think creatively and come up with unconventional ideas. They use a SIPOC model to map out the elements of their prototype concepts. The goal is to generate innovative solutions and get students building tangible prototypes early in the process through an experimental "think-while-prototyping" approach.Tokyo-Tech 2017 EDP-A #1 Team Building

Tokyo-Tech 2017 EDP-A #1 Team BuildingMasanori Kado

?

This document outlines the agenda and activities for a team building exercise. The exercise involves engineering design students drawing pictures of their team members, identifying their strengths, creating hypothetical business plans by combining members' strengths, and discussing what allows some teams to create "WOW" products while others only receive "Thank you" feedback. The goal is for teams to learn how to exploit members' strengths and work together effectively to achieve psychological safety, an important factor in high performing teams. Students are encouraged to share ideas and discuss lessons learned.実践リーンエンタープライズ(20161027)

実践リーンエンタープライズ(20161027)Masanori Kado

?

実践リーンエンタープライズ

Barry O'Reilly 来日講演会スライド(2016-10-27)

https://waicrew.doorkeeper.jp/events/50989中高生のための夏休みプログラミング教室

中高生のための夏休みプログラミング教室Masanori Kado

?

中高生のための夏休みプログラミング教室

―大学生から学ぶはじめてのプログラミング―

主催 : 東京工業大学CBECプログラム

http://cbec-titech.connpass.com/event/34596/优れた研究论文の书き方―7つの提案

优れた研究论文の书き方―7つの提案Masanori Kado

?

オリジナルはこちら

https://www.microsoft.com/en-us/research/academic-program/write-great-research-paper/

http://research.microsoft.com/en-us/um/people/simonpj/papers/giving-a-talk/Writing%20a%20paper%20(seven%20suggestions).pptx

新しいバージョンはこちら

/kdmsnr/how-to-write-a-great-research-paper-226669082Ad

罢惭厂検定4级を受けたときのメモ

- 2. 変わらないもの ? 人間賛歌 ? 人は働くことを通じて、やりがいを 感じる ? 逆に変わるもの: ? 技術、スキル、ノウハウ

- 3. 自律的なチーム ? 考える ? 誰が顧客? ? チームの目的や目標は? ? 日々どんな行動をすればいいか? ? 研究する姿勢

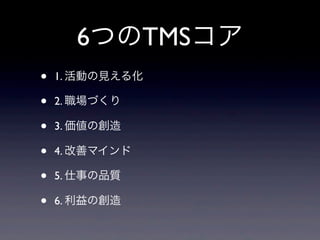

- 4. 6つのTMSコア ? ? ? ? ? ? 1. 活動の見える化 2. 職場づくり 3. 価値の創造 4. 改善マインド 5. 仕事の品質 6. 利益の創造

- 5. 1. 活動の見える化

- 6. 活動の見える化 ? 見えないものは改善できない ? 暗黙知から形式知へ ? 異常や問題をすぐに検知できる ? 現実の情報を管理する(Fact Control)

- 7. 大部屋 ? 見える化を実現する部屋 ? すべての職種が同じ部屋で仕事 ? コミュニケーションの活性化 ? アイデアの創造

- 8. 方針展開 ? 会社の方針を現場に展開する ? すり合わせで具体的行動につなげる ? 価値観や顾客の认识の统一と贵骋础

- 9. 日常のマネジメント ? マネジメントとは、仕事をしやすい環 境を作ること ?進 管理ではない! ? 現場とのすり合わせが必須 ? ビジュアルボードで「目で见る管理」

- 11. 2. 職場づくり

- 13. リーダーシップ

- 14. 3. 価値の創造

- 16. ふりかえり ? KPT

- 17. 4. 改善マインド

- 20. 問題解決 ? FGA ? なぜなぜ5回 ? 真因

- 21. 5. 仕事の品質

- 24. 6. 利益の創造

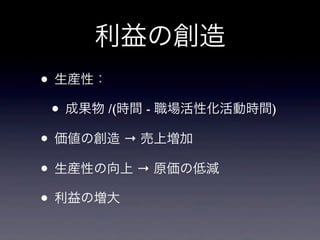

- 25. 利益の創造 ? 生産性: ? 成果物 /(時間 - 職場活性化活動時間) ? 価値の創造 → 売上増加 ? 生産性の向上 → 原価の低減 ? 利益の増大

- 26. 導入方法 ? 3か月~6か月:やりがいを感じる ? プラクティス導入 → 生産性向上 → 組 織変革 → 従業員満足 → 顧客満足

- 27. 評価 ? 自己評価 → 職場活性化活動評価シート ? 第三者評価 → 経営?組織評価シート ? 金額に関わる改善活動は、チームが前 向きになって初めて継続できる