Operasyonel MÞkemmellik Analizi

- 2. Operasyonel MÞkemmellik (OpEx) OpEx iÅletmelerin âyalÄąn ve çevik Þretimâ ilkeleri doÄrultusunda, mevcut performanslarÄąnÄą on-line olarak analiz edebilmelerine, hangi alanlarda eksiklikleri olduklarÄąnÄą gÃķrebilmelerine olanak saÄlamak Þzere geliÅtirilmiÅtir. Detay literatÞr taramasÄą ve sektÃķr araÅtÄąrmasÄąnÄąn bÞtÞnleÅik bir modu olan OpEx sektÃķrdeki ilk on-line deÄerlendirme aracÄądÄąr. OpEx, Toplam 6 FaktÃķr ve bunlara baÄlÄą 21 Alt FaktÃķrÞ, seçme 140 soru ile deÄerlendirmektedir. Sorular eÅit aÄÄąrlÄąÄa sahip deÄildir. www.leanoïŽs.com Ėý Ėý

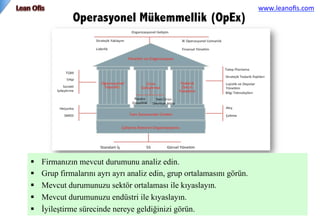

- 3. Operasyonel MÞkemmellik (OpEx) §ï§âŊ FirmanÄązÄąn mevcut durumunu analiz edin. §ï§âŊ Grup firmalarÄąnÄą ayrÄą ayrÄą analiz edin, grup ortalamasÄąnÄą gÃķrÞn. §ï§âŊ Mevcut durumunuzu sektÃķr ortalamasÄą ile kÄąyaslayÄąn. §ï§âŊ Mevcut durumunuzu endÞstri ile kÄąyaslayÄąn. §ï§âŊ Ä°yileÅtirme sÞrecinde nereye geldiÄinizi gÃķrÞn. www.leanoïŽs.com Ėý Ėý

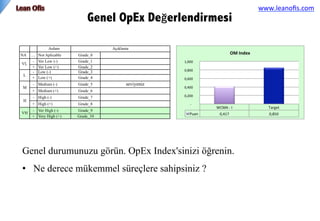

- 4. Genel OpEx DeÄerlendirmesi Genel durumunuzu gÃķrÞn. OpEx Index'sinizi ÃķÄrenin. âĒâŊ Ne derece mÞkemmel sÞreçlere sahipsiniz ? www.leanoïŽs.com Ėý Ėý

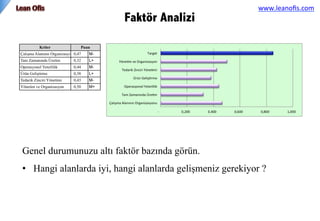

- 5. FaktÃķr Analizi Genel durumunuzu altÄą faktÃķr bazÄąnda gÃķrÞn. âĒâŊ Hangi alanlarda iyi, hangi alanlarda geliÅmeniz gerekiyor ? www.leanoïŽs.com Ėý Ėý

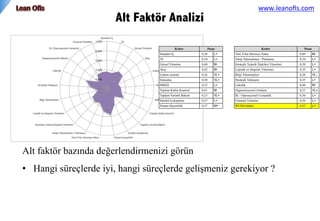

- 6. Alt FaktÃķr Analizi Alt faktÃķr bazÄąnda deÄerlendirmenizi gÃķrÞn âĒâŊ Hangi sÞreçlerde iyi, hangi sÞreçlerde geliÅmeniz gerekiyor ? www.leanoïŽs.com Ėý Ėý

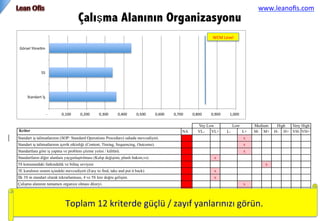

- 7. ÃalÄąÅma AlanÄąnÄąn Organizasyonu Toplam Ėý12 Ėýkriterde ĖýgÞçlÞ Ėý/ ĖýzayÄąf ĖýyanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý www.leanoïŽs.com Ėý Ėý

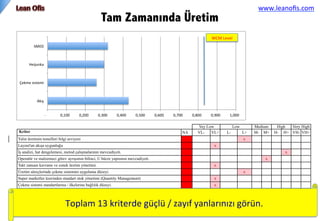

- 8. Tam ZamanÄąnda Ãretim Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Toplam Ėý13 Ėýkriterde ĖýgÞçlÞ Ėý/ ĖýzayÄąf ĖýyanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý www.leanoïŽs.com Ėý Ėý

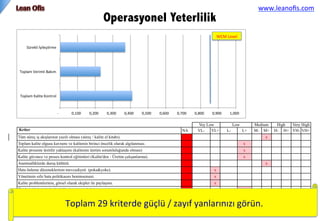

- 9. Operasyonel Yeterlilik Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Toplam Ėý29 Ėýkriterde ĖýgÞçlÞ Ėý/ ĖýzayÄąf ĖýyanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý www.leanoïŽs.com Ėý Ėý

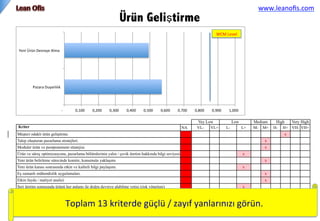

- 10. ÃrÞn GeliÅtirme Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Toplam Ėý13 Ėýkriterde ĖýgÞçlÞ Ėý/ ĖýzayÄąf ĖýyanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý www.leanoïŽs.com Ėý Ėý

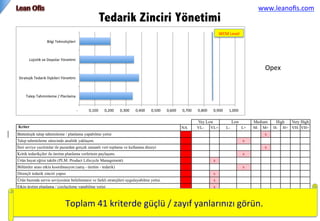

- 11. Tedarik Zinciri YÃķnetimi Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Toplam Ėý41 Ėýkriterde ĖýgÞçlÞ Ėý/ ĖýzayÄąf ĖýyanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý www.leanoïŽs.com Ėý Ėý Opex Ėý

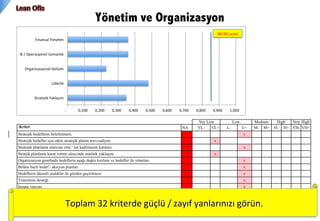

- 12. YÃķnetim ve Organizasyon Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Kriter ĖýbazÄąnda Ėý gÞçlÞ Ėý/ ĖýzayÄąf Ėý yanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý Toplam Ėý32 Ėýkriterde ĖýgÞçlÞ Ėý/ ĖýzayÄąf ĖýyanlarÄąnÄązÄą ĖýgÃķrÞn. Ėý

- 13. OpEx Assesment §ï§âŊ FirmanÄązÄą analiz edin. §ï§âŊ Grup firmalarÄąnÄą ayrÄą ayrÄą analiz edin, grup ortalamasÄąnÄą gÃķrÞn. §ï§âŊ Mevcut durumunuzu sektÃķr ortalamasÄą ile kÄąyaslayÄąn. §ï§âŊ Mevcut durumunuzu endÞstri ile kÄąyaslayÄąn. §ï§âŊ Ä°yileÅtirme sÞrecinde nereye geldiÄinizi gÃķrÞn.